1.High Chromium cast iron composite roller tire material

Hana ʻia ka ʻōwili hao hao kiʻekiʻe me ka hao hao kiʻekiʻe e like me ka mea matrix, ma o ke kaʻina hana kūikawā, ka hao hao kiʻekiʻe a me ka honeycomb ceramic particles composite molding, ceramic ZTA ceramic particles, a laila ma o ke kaʻina hana hoʻolei one, ka hui hao hao kiʻekiʻe a me ka hoʻoheheʻe ʻana i ka hao ductile. Hōʻike ʻia ka hoʻohui kemika o ka mea hao hao kiʻekiʻe ma ka Papa 1 ma lalo nei.

Papa 1: Ka hoʻohuihui kemika o ka wili hao hao kiʻekiʻe chromium (wt%)

| Mea Hana | C | Si | Mn | S | P | Cr |

| ʻO ke kaila wili hao seramika kiʻekiʻe chromium | 2.8-3.2 | 0.5-1.0 | 0.5-1.2 | ≤0.05 | ≤0.05 | 20-26 |

| Hao ductile | 3.2-3.9 | 2.5-2.7 | 0.3~0.5 | ≤0.04 | ≤0.04 |

2. Waiwai mīkini

ʻO ke kaila wili hao keramika kiʻekiʻe chromium he molding composite lua o ka hao cast chromium kiʻekiʻe, nā ʻāpana keramika ZTA a me ka hao ductile, ka mea e hana ai i ka ʻūlū wili keramika ʻaʻole wale ka ikaika a me ka paʻakikī, akā he paʻakikī kiʻekiʻe hoʻi, e hōʻoiaʻiʻo ana i ke kūpaʻa ʻaʻahu a me ka palekana o ka ʻūlū wili. ʻOi aku ka paʻakikī o nā ʻāpana keramika ZTA ma mua o HV2100, ʻoiai ʻoi aku ka paʻakikī o ka hao cast chromium kiʻekiʻe M7C3 carbide ma mua o HV1400, a ʻoi aku ka paʻakikī o ka matrix hao cast chromium kiʻekiʻe ma mua o HV750, no laila, ma lalo o ke kūlana o ke kaumaha kiʻekiʻe abrasive ʻelua kino kiʻekiʻe stress wear, ma muli o ka ʻokoʻa o nā mea, ʻo ke ola lawelawe o ka ʻūlū wili keramika he 1.5-3 mau manawa o ka ʻūlū wili hao cast chromium kiʻekiʻe maʻamau. Hōʻike ʻia nā waiwai o ka hao cast chromium kiʻekiʻe a me ka hao ductile ma ka Papa 2 ma lalo nei.

Papa 2: Waiwai Mekanika

| Mea Hana | Ikaika tensile /Mp | Paʻakikī o ka hopena J/kenimika2 | Paʻakikī/HRC | Ka helu o ka hoʻolōʻihi ʻana(%) |

| Chrome kiʻekiʻe | ≥800 | ≥4 | ≥60 | --- |

| Hao Ductile | 500~650 | ---- | 147~241(HB) | 4~10 |

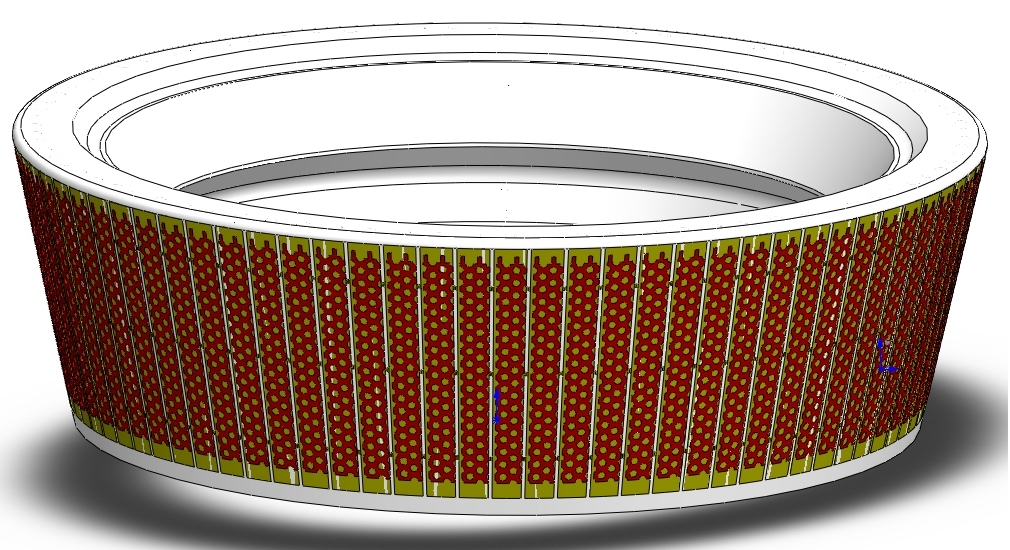

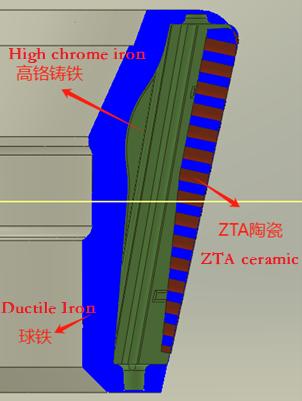

3. Hoʻolālā ʻano o ka huila huila seramika hao kiʻekiʻe chromium

Ua hōʻike ʻia ka hoʻolālā hoʻonohonoho o ka ʻōwili hao keramika hao kiʻekiʻe i ke Kiʻi 1 a me ke Kiʻi 2 ma lalo. ʻO ka ʻāpana meli ʻulaʻula ka ʻāpana hoʻolaha ʻāpana keramika ZTA. Hoʻolaha ʻia nā ʻāpana keramika i loko o ka matrix alloy chromium kiʻekiʻe i loko o kahi ʻano meli, a uhi ka papa keramika i ka ʻāpana hana o ka ʻōwili holoʻokoʻa. ʻO ka ʻāpana ʻōmaʻomaʻo ma waho o ka papa keramika he hao hoʻolei chromium kiʻekiʻe, a ʻo ka ʻāpana polū he hao ductile.