1. Izinto zethayi le-roller elihlanganisiweyo le-Chromium ephezulu

Isingxobo serolari esidityanisiweyo se-ceramic esine-chromium ephezulu senziwe ngesinyithi esidityanisiweyo se-chromium ephezulu njengezinto ze-matrix, ngenkqubo ekhethekileyo, isinyithi esidityanisiweyo se-chromium ephezulu kunye nee-honeycomb ceramic particles, ii-ceramic particles ze-ZTA, kwaye emva koko ngenkqubo yokuphosa isanti, i-ceramic composite ye-chromium ephezulu kunye ne-ductile iron secondary composite molding. Ukwakheka kweekhemikhali kwezinto zesinyithi ezidityanisiweyo ze-chromium ephezulu kuboniswe kwiTheyibhile 1 ngezantsi.

Itheyibhile 1: Ukwakheka kweekhemikhali zerola yentsimbi edityanisiweyo ene-chromium ephezulu (wt%)

| Izinto eziphathekayo | C | Si | Mn | S | P | Cr |

| Itayara yerolari edityanisiweyo yesinyithi esine-chromium ephezulu | 2.8-3.2 | 0.5-1.0 | 0.5-1.2 | ≤0.05 | ≤0.05 | 20-26 |

| Isinyithi esithambileyo | 3.2-3.9 | 2.5-2.7 | 0.3~0.5 | ≤0.04 | ≤0.04 |

2. Ipropati yoomatshini

Ithayara le-roller elihlanganisiweyo le-chromium cast iron ephezulu yi-molding yesibini ye-chromium cast iron ephezulu, ii-ZTA ceramic particles kunye ne-ductile iron, nto leyo eyenza i-ceramic composite roller sleeve ingabi namandla aphezulu kunye nobunzima kuphela, kodwa ikwanobunzima obuphezulu, okuqinisekisa ukumelana nokuguguleka kunye nokhuseleko lwe-roller sleeve. Ubunzima be-ZTA ceramic particle bungaphezulu kwe-HV2100, ngelixa ubunzima be-chromium cast iron M7C3 carbide bungaphezulu kwe-HV1400, kwaye ubunzima be-chromium cast iron matrix bungaphezulu kwe-HV750, ngoko ke, phantsi kwemeko ye-abrasive ephezulu yoxinzelelo oluphezulu imizimba emibini yoxinzelelo oluphezulu, ngenxa yomahluko kwizinto, ubomi benkonzo ye-ceramic composite roll sleeve buphindwe ka-1.5-3 kune-chromium eqhelekileyo cast iron roll sleeve. Iimpawu ze-chromium cast iron ephezulu kunye ne-ductile iron ziboniswe kwiTheyibhile 2 ngezantsi.

Itheyibhile 2: Iipropati zoomatshini

| Izinto eziphathekayo | Amandla okutsalwa /Mp | Ukuqina Kwempembelelo J/cm2 | Ubunzima/i-HRC | Izinga lobude (%) |

| I-Chrome ephezulu | ≥800 | ≥4 | ≥60 | --- |

| Intsimbi ethambileyo | 500~650 | ---- | 147~241(HB) | 4~10 |

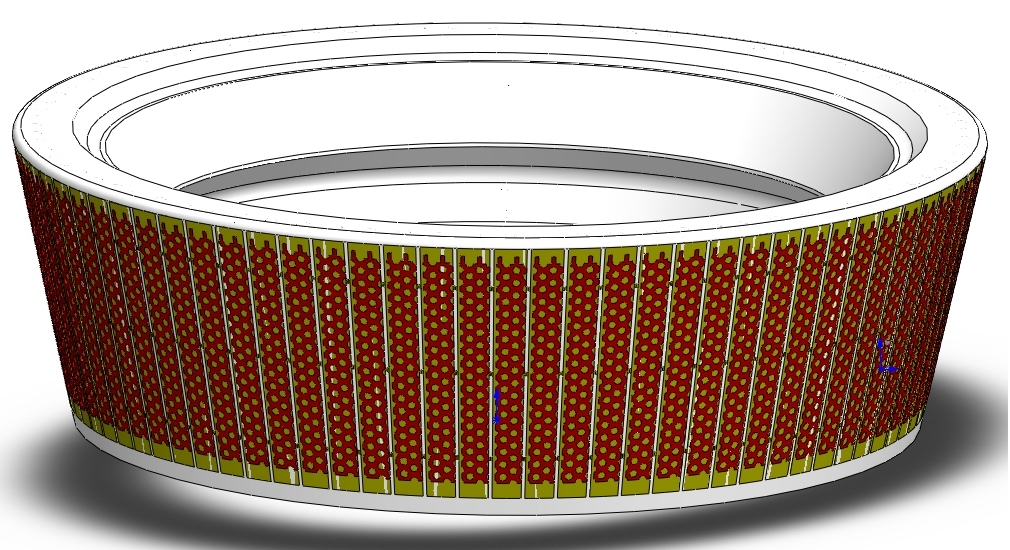

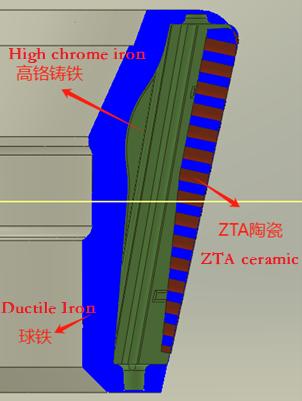

3. Uyilo lolwakhiwo lwetayara yerolari edityanisiweyo yesinyithi esine-chromium ephezulu

Uyilo lwesakhiwo sesilayidi serolari esidityaniswe ne-chromium ephezulu cast iron ceramic luboniswe kuMfanekiso 1 kunye noMfanekiso 2 ngezantsi. Indawo yehoneycomb ebomvu yindawo yokusasazwa kwamasuntswana e-ceramic amelana nokuguguleka e-ZTA. Amasuntswana e-ceramic asasazwa kwi-matrix ephezulu ye-chromium alloy kwisakhiwo sehoneycomb, kwaye umaleko we-ceramic ugubungela indawo yokusebenza yokuguguleka kwesilayidi yonke. Indawo eluhlaza ngaphandle komaleko we-ceramic yi-chromium ephezulu cast iron, kwaye indawo eluhlaza okwesibhakabhaka yi-ductile iron.